도로 표시 기계의 책임 있는 소유주로서, 당신은 이 기계에 대한 적시 유지 보수를 제공하기 위해 몇 가지 주의사항을 고려해야 합니다.

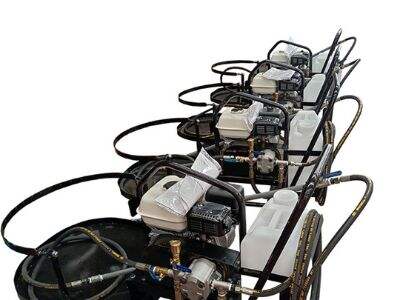

당신의 도로 표시 기계의 유지 보수는 기계를 깨끗이 유지하는 것에서 시작됩니다. 간단해 들릴 수 있지만, 매우 중요합니다! 시간이 지남에 따라 먼지, 티끌 및 잔해가 기계 내부에 쌓여 문제가 발생하거나 기계가 고장날 수 있습니다. 이를 방지하려면 기계를 청소하세요. 비트우민 분사기 사용 후 잘 청소하세요. 물이 든 부드러운 천으로 닦아주는 것이 좋습니다. 깨끗한 기계는 더 잘 작동합니다. 조인트 균열 채우기 재료 더 나아지고 더 오래 지속됩니다.

기계의 유체 수준을 정기적으로 확인하는 것도 유지 관리의 중요한 부분입니다. 이것은 페인트, 희석제 및 윤활유의 수준과 관련이 있습니다. 아스팔트 분산기 수준이 너무 낮으면 기계가 제대로 작동하지 않거나 아예 멈출 수 있습니다. 기계를 사용하기 전에 이러한 수준을 확인하는 습관을 들이세요. 또한 기계의 필터를 정기적으로 점검해야 합니다. 필터는 흙과 페인트로 막힐 수 있으므로, 더러워 보이거나摩耗된 경우 교체 계획을 세우세요.

도로의 안전을 유지하기 위한 관리 팁

기계를 사용하기 전에 도로 표시 기계 검사를 수행하여 모든 것이 정상적으로 작동하고 있는지 확인하는 것이 현명합니다. 준비 단계에서 가장 중요한 단계 중 하나는 기계를 사용 준비 상태로 만드는 것입니다. 페인트의 적용과 상태를 검사해야 합니다. 또한 기계의 파이프에 페인트 흐름을 방해할 수 있는 막힘이나 장애물이 없는지 확인하십시오.

기계의 브러시와 롤러를 정기적으로 교체하는 것도 중요합니다. 이러한 부품은 도로 위에 깨끗하고 선명한 선을 그리는 데 필수적입니다. 시간이 지남에 따라 롤러와 브러시가摩耗되어 표시 품질이 저하될 수 있습니다. 이를 자주 교체하면 기계의 성능이 향상되고 도로에 못看한 선이 생기는 것을 방지할 수 있습니다.

EN

EN

AR

AR

NL

NL

EL

EL

KO

KO

RU

RU

VI

VI